Turnkey Solution for New Energy Intelligent Equipment

2025-03-03

Steel Strip of Battery Module: Why Do We Still Need Humans to Step in at the Moment When the Squeezing Platform Is Released?

Imagine you are assembling an oversized "battery building block" - automated equipment inserts the battery cells into the squeezing platform and stacks them layer by layer, just like adding ingredients to a sandwich. With a "buzz" from the hydraulic ...

2025-03-03

Battery Ultrasonic Welding Equipment: Opening a New Realm of Battery Manufacturing

In the surging wave of the rapid development of the new energy industry, batteries, as the key energy storage carriers, the precision of their manufacturing processes directly determines the performance and market competitiveness of products. And the...

2025-02-12

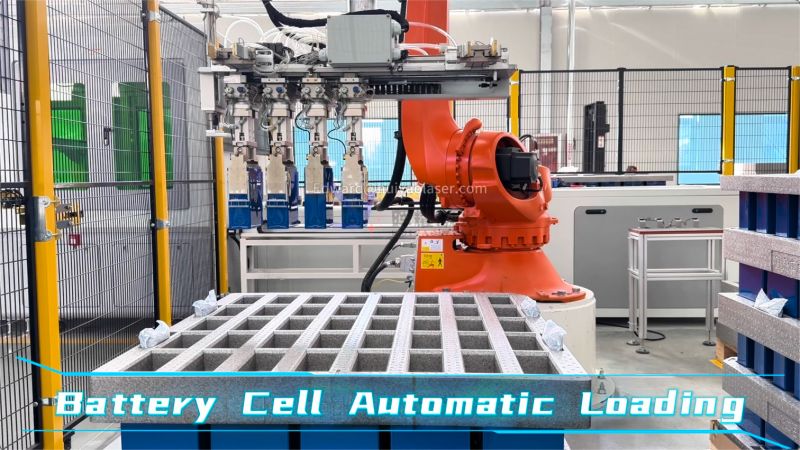

How to Assemble a Prismatic Battery PACK for ESS: The Role of Robotic Arm Cell Loading

As the demand for Energy Storage Systems (ESS) grows exponentially, the need for efficient and reliable assembly processes for prismatic battery PACKs has become more critical than ever. A key step in this assembly line is the cell loading process, w...

2025-02-08

Dual-station closed rotary welding machine: Innovative welding technology leads the new direction of modern manufacturing

In today's environment where manufacturing industry continues to pursue high efficiency, high quality and automation, welding technology is also constantly innovating. Dual-station closed rotary welding machine is an innovative welding equipment that...

2025-02-06

Advantages of automatic glue coating machines in PACK glue coating

With the rapid development of the energy storage and power battery industries, the production process requirements of battery modules (PACKs) are getting higher and higher. As a key link in PACK production, its efficiency and quality directly affect ...

2025-01-14

Blade Batteries: Redefining the Safety and Efficiency of Battery Modules

Introduction Today, with the rapid development of new energy vehicles, battery technology is the core competitiveness of the industry. The blade battery launched by BYD not only redefines the form of the battery module with its unique structura...

Email: sales@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.