Turnkey Solution for New Energy Intelligent Equipment

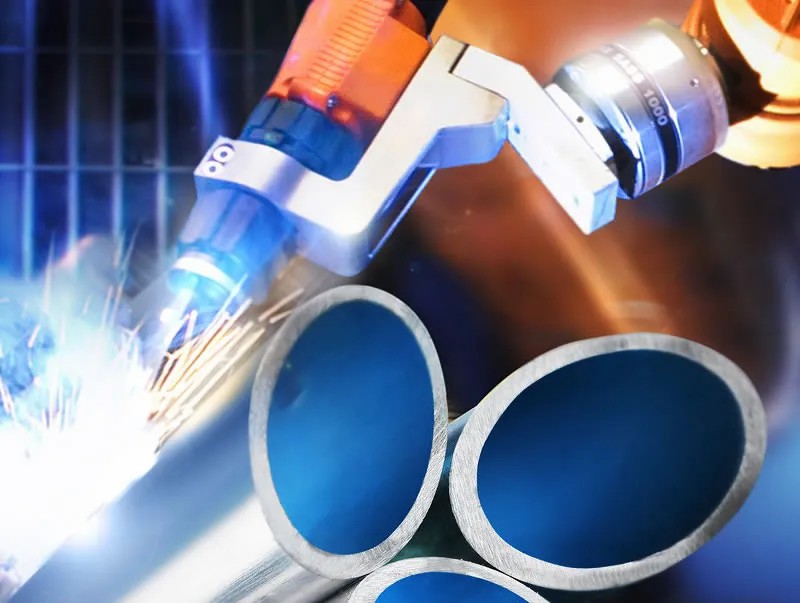

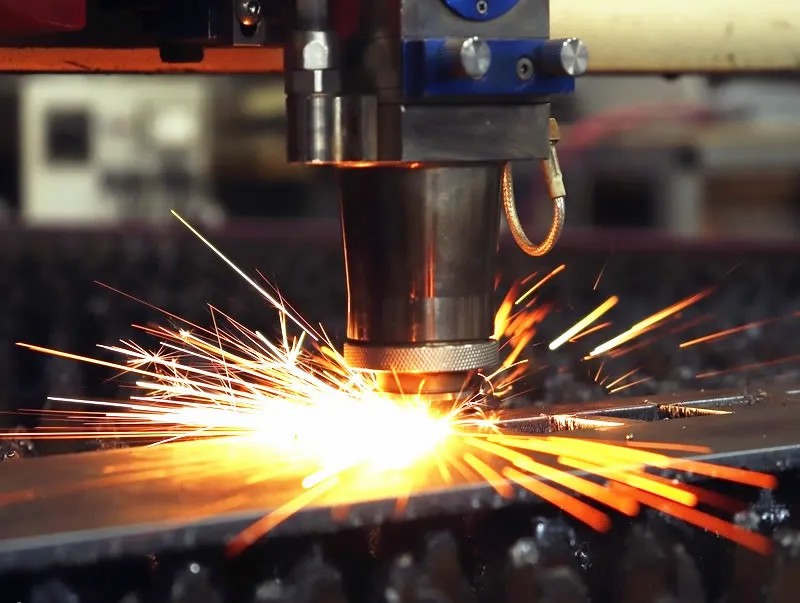

Laser welding technology

Laser welding is a high-precision, non-contact welding technology that utilizes a high-energy laser beam to achieve precise welding of battery components. This technology provides high-quality welding connections while reducing the risks of heat impact and deformation. Laser welding is one of the key technologies in battery module PACK production lines. By harnessing the high energy focus and instantaneous heating of the laser beam, precise welding connections are achieved, ensuring high quality and reliable battery assembly.

Quality control technology

Battery module PACK production lines rely on stringent quality control to ensure the consistency and reliability of each component. Yao Laser's equipment is equipped with advanced quality control technology and testing devices to verify and assess the quality, performance, consistency, and reliability of battery components.

Intelligent control system

Yao Laser's equipment utilizes an intelligent control system, leveraging advanced algorithms and sensor technology to achieve real-time monitoring and adjustment of the production process. This intelligent control system enhances production efficiency, consistency, and fault detection capabilities. Yao Laser's equipment adopts an intelligent control system, utilizing advanced algorithms and sensor technology to achieve real-time monitoring and adjustment of the production process. This intelligent control system enhances production efficiency, consistency, and fault detection capabilities.

Flexible module design capability

Yao Laser's equipment allows for flexible module design to meet the needs of different customers. It can accommodate battery module PACKs of varying sizes, formats, and chemical compositions, supporting the requirements of various applications and industries.

Data management and traceability capability

Yao Laser's equipment is typically equipped with advanced data management and traceability systems. These systems record and manage key data during the production process, including production parameters, process settings, and quality inspection results. Through traceability capability, you can track the production history and quality data of each battery module PACK, ensuring that the products meet standards and quality requirements.

System integration and collaborative capabilities

Yao Laser's battery module PACK line equipment has collaborative capabilities, enabling seamless integration with other production equipment and systems. This collaborative capability allows the entire production line to operate efficiently and improves overall production efficiency and performance. The equipment is equipped with collaborative capabilities to seamlessly integrate with other production equipment and systems. This collaborative capability enhances the efficiency and overall performance of the entire production line.

Continuous innovation and research and development capabilities

As a technology-driven company, Yao Laser continuously engages in innovation and research and development to advance the development of battery module PACK production line equipment. The team focuses on industry trends and customer demands, actively improving equipment performance, functionality, and applicability. yao Laser continuously innovates and conducts research and development, paying attention to industry trends and customer needs. The company is committed to enhancing equipment performance, functionality, and applicability to meet the evolving demands of the energy storage market.

Email: sales@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.