Turnkey Solution for New Energy Intelligent Equipment

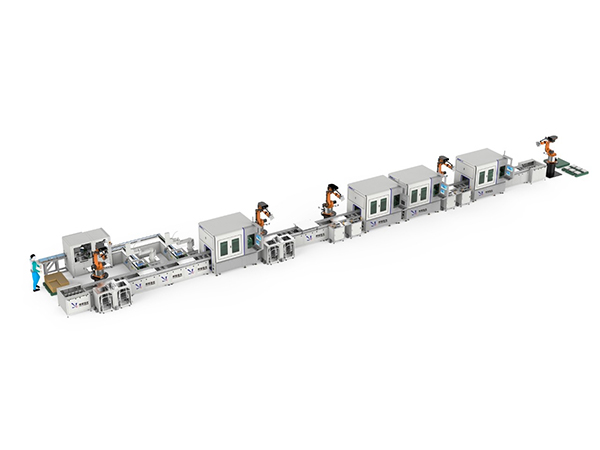

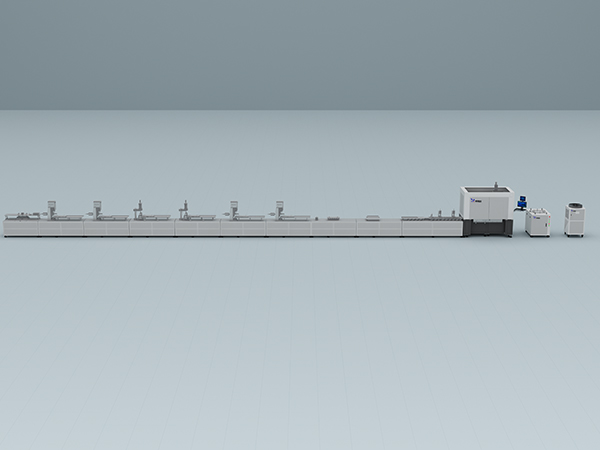

EV Prismatic Battery Module PACK Assembly Line

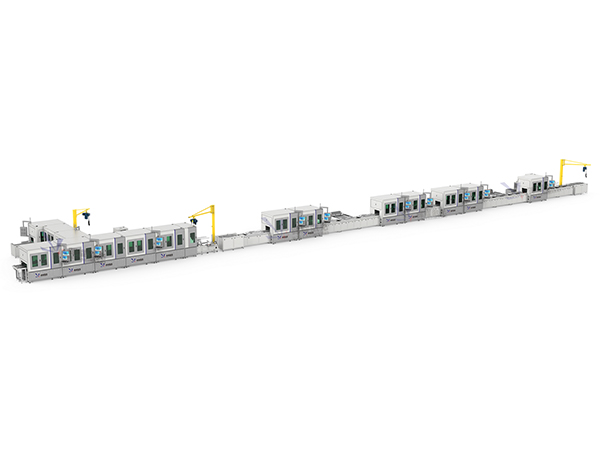

EV Pouch Battery Module PACK Line

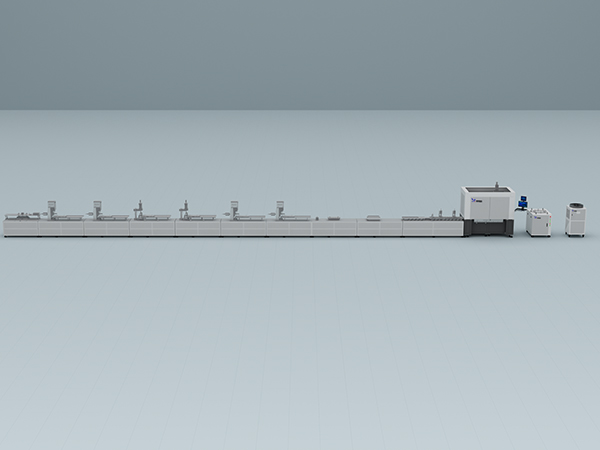

EV Blade Battery Module PACK Line

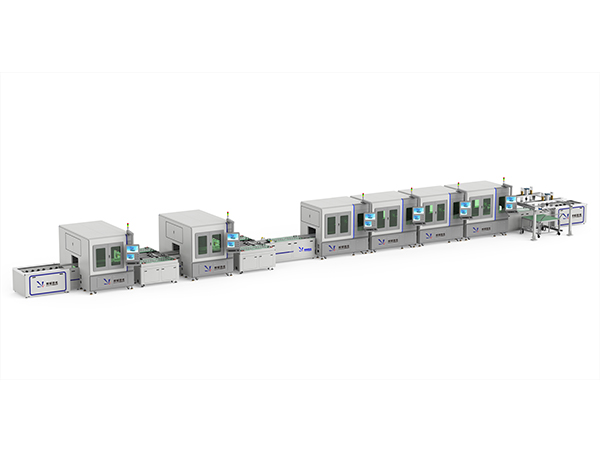

EV Prismatic Battery CTP Automatic Welding Line

EV Blade Battery CTP Automatic Welding Line

Robot Laser Welding Workstation

Battery Cell Module PACK Testing Equipment

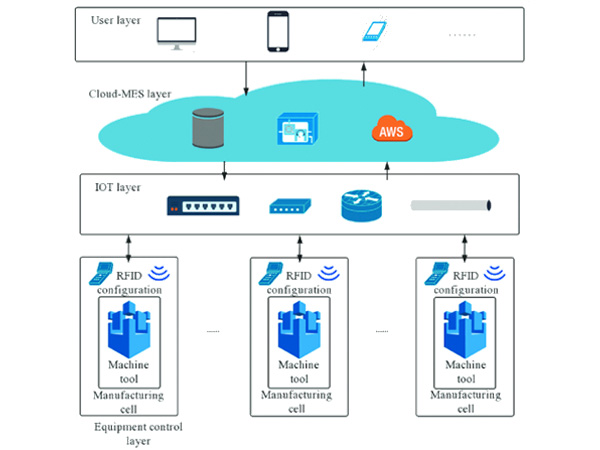

MES Solutionfor EV Smart Factory

Yaolaser provide a complete smart factory solution for new energy vehicle power battery manufacturing, specializing in automated module and PACK production for prismatic, pouch, and blade batteries. Through advanced laser welding technology, robotic automation, and intelligent inspection systems, we help customers achieve high-efficiency, high-precision, and highly consistent battery manufacturing.

|

Key Metric |

Traditional Line |

Our Smart Line |

Improvement |

|

Production Efficiency |

8 PPM |

12 PPM |

15%↑ |

|

Product Yield |

98% |

99.8% |

1.8%↑ |

|

Labor Cost |

100% |

30% |

70%↓ |

|

Energy Consumption |

Baseline |

25% reduction |

Significant |

|

Changeover Time |

8 hours |

2 hours |

75%↓ |

We offer free consultation and competitive quotations to help build your leading-edge battery smart factory!

Choose Us for Efficient, Intelligent, and Reliable Battery Manufacturing!

|

Product Line |

Yield Rate |

Energy Saving |

|

Prismatic Module Line |

≥99.6% |

22% |

|

Pouch Battery Line |

≥99.3% |

25% |

|

Blade Battery Line |

≥99.7% |

28% |

Huiyao Laser Technology (Luoyang) Co., Ltd. is a professional provider of EV battery smart factory solutions, specializing in automated production systems for next-generation battery manufacturing. With 15+ years of experience in laser processing and automation, we deliver cutting-edge technologies tailored to EV battery production needs.

1.Q: Can these production lines be customized for different battery chemistries?

A: Yes, our systems support LFP, NMC, and future battery chemistries.

2.Q: What's the lead time for a complete solution?

A: Typically 6-9 months depending on configuration and customization.

3.Q: Do you provide operator training?

A: Comprehensive training programs covering operation, maintenance and troubleshooting are included.

4.Q: How does the MES system handle data security?

A: Our system features multi-level encryption and access control.

5.Q: What maintenance services do you offer?

A: We provide preventive maintenance plans, spare parts management, and remote diagnostics.

Email: sales@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.