Turnkey Solution for New Energy Intelligent Equipment

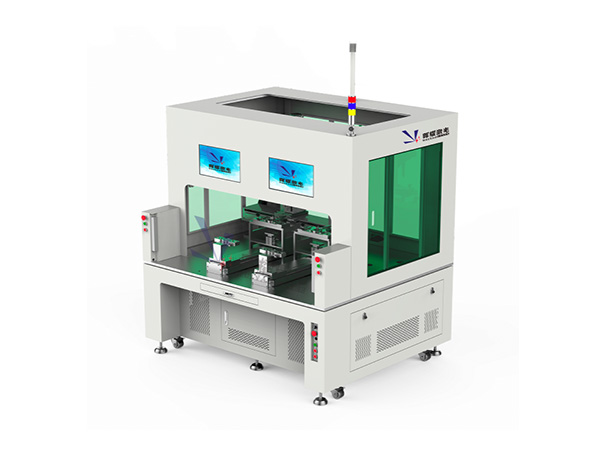

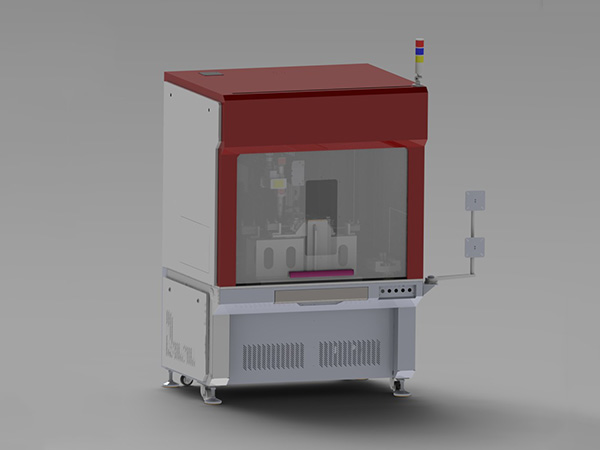

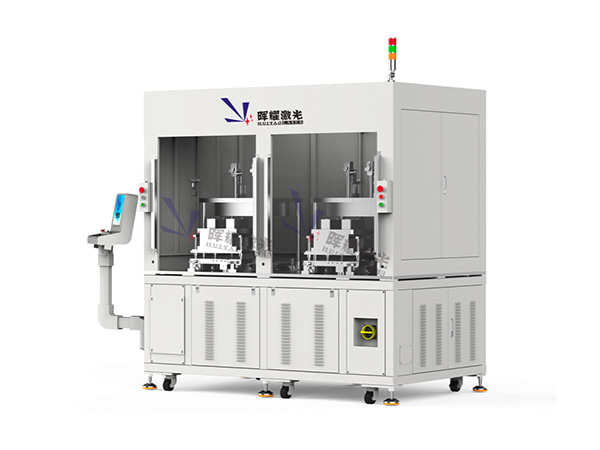

Equipment Name: Automatic Explosion-Proof Valve Welding Machine Model: HY-EPVW300 Application: Specialized in precise laser welding of explosion-proof valves for prismatic and cylindrical batteries, ensuring a robust and airtight weld to meet high safety standards. Production Capacity: 20–30 valves per minute.

Categories: Laser Welding Machine REQUEST FOR QUOTE > TURN BACKEquipment Name: Automatic Explosion-Proof Valve Welding Machine

Model: HY-EPVW300

Application: Specialized in precise laser welding of explosion-proof valves for prismatic and cylindrical batteries, ensuring a robust and airtight weld to meet high safety standards.

Production Capacity: 20–30 valves per minute.

Equipment Dimensions:

Length: 2000 mm

Width: 1500 mm

Height: 1800 mm

Weight: 1200 kg ± 5%

Frame Material: Industrial-grade steel with powder-coated finish for durability.

Worktable Material: High-precision aluminum alloy with an anti-static coating.

Motion System: Servo-controlled X-Y-Z axes for high-accuracy operation.

Welding Technology: Precision Fiber Laser Welding.

Laser Specifications:

Wavelength: 1064 nm

Power: 200–500 W (adjustable)

Beam Diameter: 0.1–0.3 mm

Welding Speed: Up to 3 seconds per weld.

Welding Accuracy: ±0.02 mm.

Material Compatibility: Aluminum, stainless steel, and nickel-plated steel.

Valve Size Compatibility:

Diameter: 5–50 mm

Thickness: 0.2–2 mm

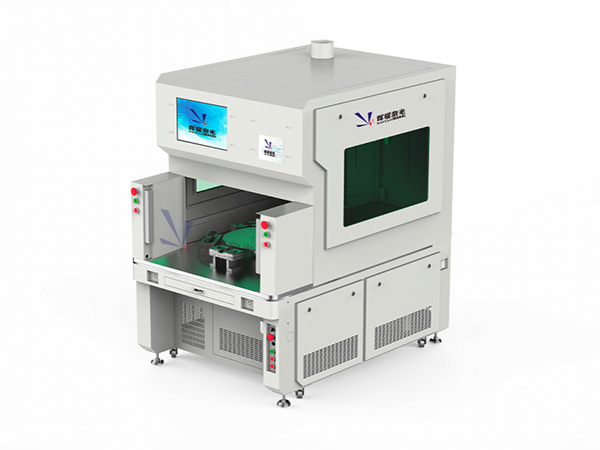

Automation:

Automatic loading via vibration feeder or robotic arm.

Pneumatic unloading system for finished parts.

Capacity:

Input Hopper: 500 valves per batch.

Output Bin: 500 welded valves.

Alignment Accuracy: ±0.02 mm.

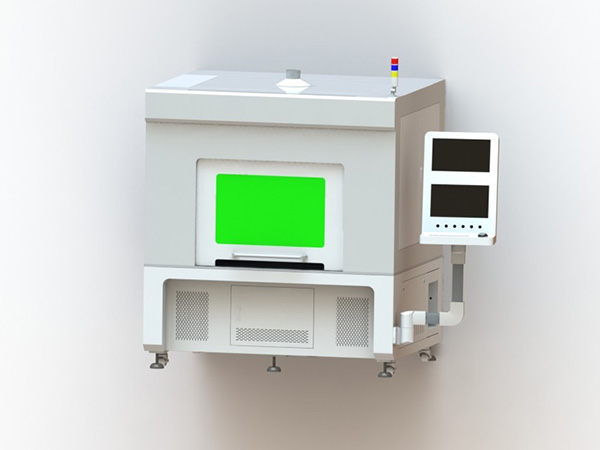

Camera Specifications:

High-resolution CCD cameras (5 MP) for alignment and inspection.

Lighting System: Adjustable LED with anti-glare diffusers for optimal visibility.

Inspection Features:

Pre-weld alignment verification.

Post-weld inspection for surface integrity and dimensional accuracy.

Control System: Advanced PLC-based control with real-time process monitoring.

HMI:

12-inch capacitive touchscreen.

Multi-language support (English, Chinese, others).

Programmable Parameters:

Laser power, focus, and pulse frequency.

Welding path and cycle time.

Data Logging:

Internal Storage: 1 TB SSD for process data.

Export Formats: CSV, PDF via USB or Ethernet.

Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

Maximum Power Consumption: 8 kW.

Control Voltage: 24V DC for auxiliary systems.

Emergency Stop: Multiple emergency stop buttons accessible from all sides.

Laser Safety:

Class 1 laser enclosure with interlocks.

Protective safety glass with an optical density (OD) >5.

Overload Protection: Real-time monitoring of servo motors and laser systems.

Protective Barriers: Transparent polycarbonate enclosures.

Defect Alarms: Audible and visual alerts for misaligned valves or welding defects.

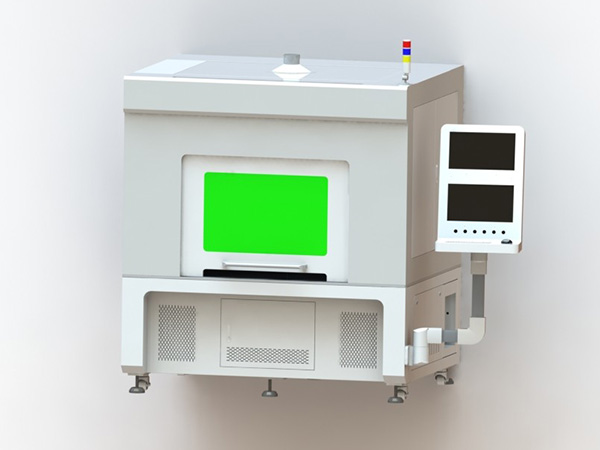

Operating Environment:

Temperature: 15–30°C

Humidity: ≤60% RH (non-condensing).

Noise Level: ≤70 dB during operation.

Installation Requirements:

Flat, vibration-free surface.

Minimum clearance: 1,000 mm on all sides.

Type: Integrated water cooling system for the laser module.

Cooling Capacity: 5 kW.

Water Flow Rate: 10–15 L/min.

Optional: Air-cooled configuration for smaller-scale operations.

Dual Laser Heads: For simultaneous welding of multiple valves.

Advanced Vision System: AI-powered defect detection and alignment adjustment.

IoT Connectivity: Remote monitoring and diagnostics via cloud.

Custom Tooling: For non-standard valve shapes or sizes.

Maintenance Schedule:

Weekly: Clean lenses and inspect laser optics.

Monthly: Calibrate laser parameters and check alignment systems.

Quarterly: Perform full diagnostics of electrical and mechanical components.

Warranty Period:

Standard: 12 months.

Extended: Up to 36 months available upon request.

Dual-Station Terminal Pole Welding Machine

Six-Station Rotary Welding Machine

Dual-Station Enclosed Rotary Welding Machine

Battery Terminal Tab Welding Equipment

Battery Terminal Tab Ultrasonic Welding Equipment

Battery Terminal Tab Transition Sheet Welding Equipment

Battery Case Insertion and Top Cap Pre-Welding Equipment

Battery Top Cap Welding Equipment

Email: sales@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.