Turnkey Solution for New Energy Intelligent Equipment

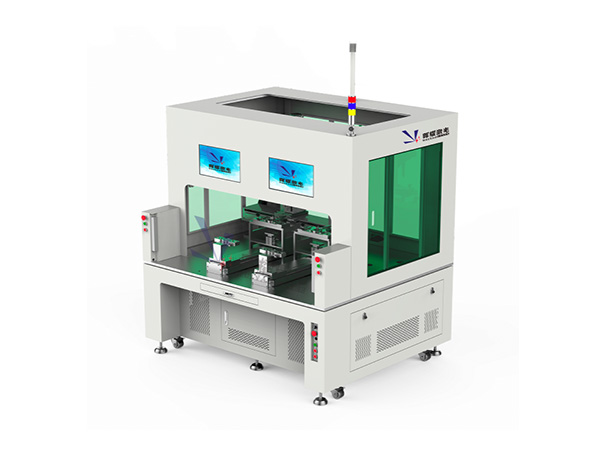

Equipment Name: Six-Station Rotary Welding Machine

Model: HY-SRW600

Application: Designed for efficient, high-precision welding of battery components or metal parts in a continuous rotary process, combining multiple welding operations into a single machine.

Production Capacity: 20–40 pieces per minute (process-dependent).

Equipment Dimensions:

Diameter: 2800 mm

Height: 2000 mm

Weight: 3500 kg ± 5%

Frame Material: Reinforced carbon steel with powder-coated finish.

Table Material: Precision-machined stainless steel with anti-static coating.

Station Indexing System:

Type: Servo-driven rotary indexing table.

Positioning Accuracy: ±0.02 mm.

Station Capacity: 6 workstations with modular tooling.

Welding Technology:

Standard: Laser Welding.

Optional: Ultrasonic or Resistance Welding.

Laser Specifications:

Power: 200–1000 W (adjustable based on application).

Wavelength: 1064 nm.

Cycle Time: ≤10 seconds per weld.

Welding Accuracy: ±0.02 mm.

Material Compatibility: Aluminum, copper, nickel, stainless steel.

Alignment Accuracy: ±0.02 mm.

Vision System:

Industrial-grade CCD cameras at multiple stations.

Inspection Speed: ≤0.5 seconds per piece.

Defect Detection: AI-based algorithms for detecting incomplete welds, cracks, or material misalignment.

Control System: PLC-based centralized system with independent modules for each station.

HMI:

15-inch capacitive touchscreen with intuitive GUI.

Multi-language support (English, Chinese, others).

Programmable Parameters:

Laser power, duration, and focus.

Station-specific settings for different components.

Data Logging:

Internal Storage: 2 TB SSD for operation and quality data.

Export Formats: CSV, PDF via USB, Ethernet, or cloud.

Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

Maximum Power Consumption: 12 kW.

Control Voltage: 24V DC for auxiliary systems

Emergency Stop: Multiple emergency stop buttons at operator stations and central control panel.

Laser Safety:

Class 1 laser enclosures with interlocks.

Protective safety curtains.

Overload Protection: Integrated sensors for detecting excessive load on motors and welding systems.

Protective Barriers: Transparent polycarbonate enclosures.

Defect Alarms: Audible and visual alerts for misalignment or weld failures.

Operating Environment:

Temperature: 15–30°C

Humidity: ≤60% RH (non-condensing).

Noise Level: ≤70 dB during operation.

Installation Requirements:

Flat, vibration-free surface.

Minimum clearance: 1,200 mm around the machine.

Type: Integrated water cooling system for laser and mechanical components.

Cooling Capacity: 10 kW.

Water Flow Rate: 10–20 L/min.

Optional: Air-cooled configuration for lower-power setups.

Additional Welding Heads: Dual welding heads for increased throughput.

Advanced Vision System: AI-based defect recognition and alignment enhancement.

IoT Connectivity: Remote monitoring and real-time diagnostics via cloud.

Automated Sorting: Integrated sorting system for good and defective parts

Maintenance Schedule:

Weekly: Clean lenses, inspect alignment systems, and check cooling units.

Monthly: Calibrate laser power and inspect rotary indexer.

Quarterly: Perform full diagnostics of electrical and mechanical systems.

Warranty Period:

Standard: 12 months.

Extended: Up to 36 months available upon request.

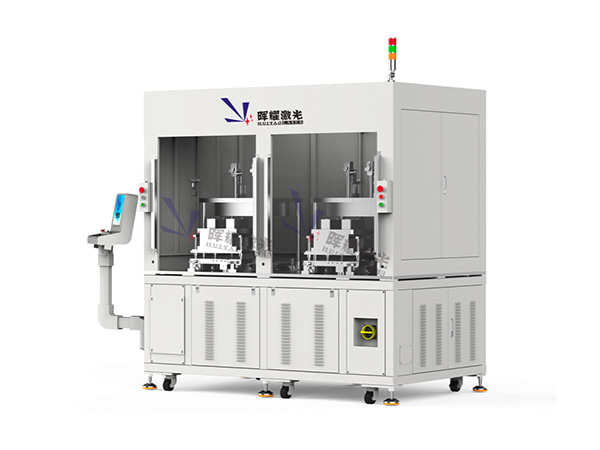

Dual-Station Terminal Pole Welding Machine

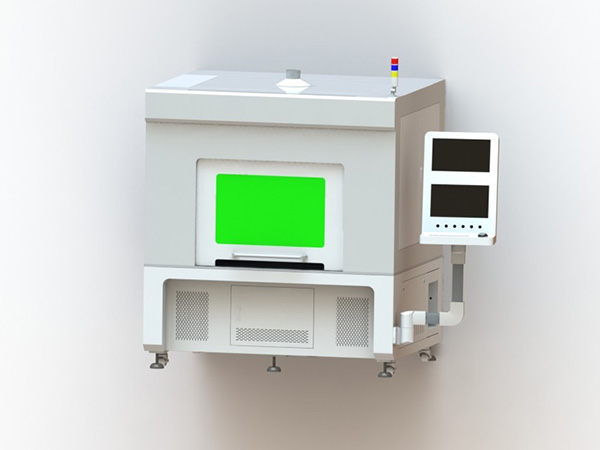

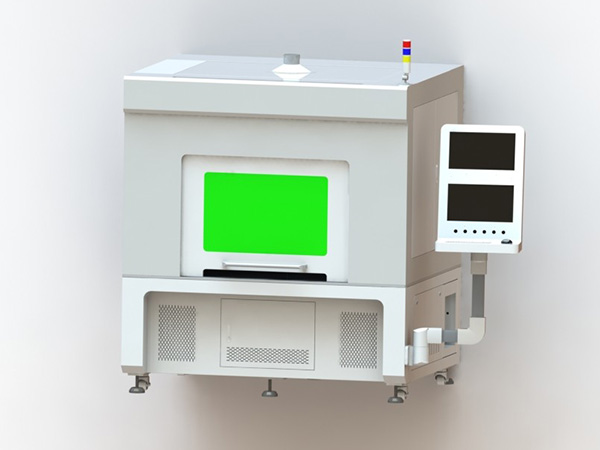

Automatic Explosion-Proof Valve Welding Machine

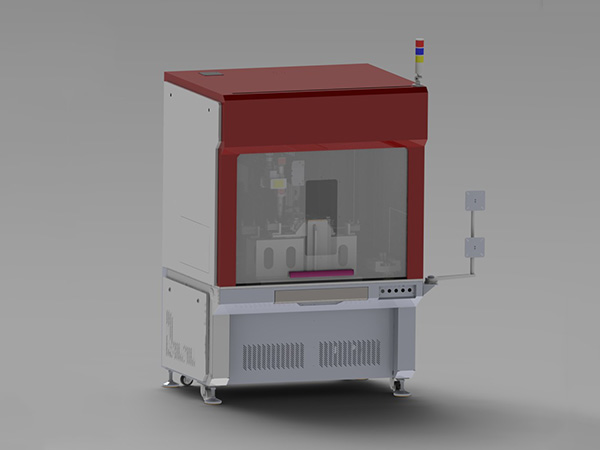

Dual-Station Enclosed Rotary Welding Machine

Battery Terminal Tab Welding Equipment

Battery Terminal Tab Ultrasonic Welding Equipment

Battery Terminal Tab Transition Sheet Welding Equipment

Battery Case Insertion and Top Cap Pre-Welding Equipment

Battery Top Cap Welding Equipment

Email: sales@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.