Turnkey Solution for New Energy Intelligent Equipment

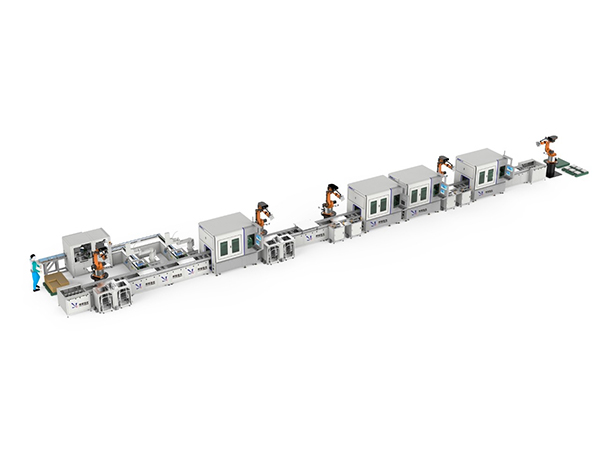

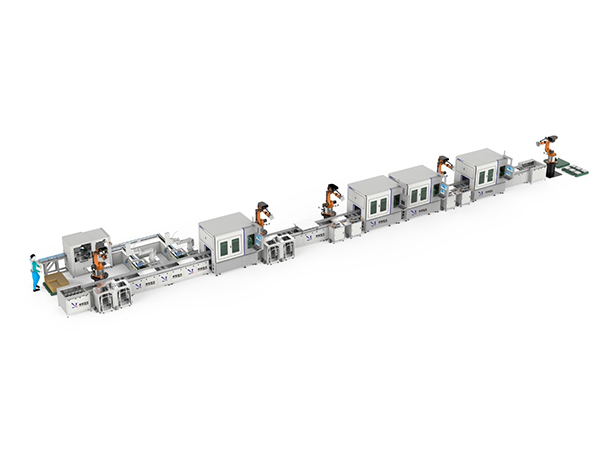

The EV Blade Battery CTP (Cell-to-Pack) Automatic Welding Line is a cutting-edge automated solution tailored for the direct assembly of blade battery cells into robust packs without intermediate modules. This line combines high-precision handling, advanced laser welding, and quality inspection systems to ensure efficient, high-throughput production while meeting the demanding safety and performance requirements of EV batteries.

Categories: Lithium Battery PACK Assembly REQUEST FOR QUOTE > TURN BACKThe EV Blade Battery CTP (Cell-to-Pack) Automatic Welding Line is a cutting-edge automated solution tailored for the direct assembly of blade battery cells into robust packs without intermediate modules. This line combines high-precision handling, advanced laser welding, and quality inspection systems to ensure efficient, high-throughput production while meeting the demanding safety and performance requirements of EV batteries.

2.1 Automatic Blade Cell Feeding and Positioning Station

Function: Automatically feeds blade cells into the line and ensures precise alignment for welding.

Specifications:

Cell Size Range: Length 400–1,200 mm, Width 80–150 mm, Thickness 10–40 mm.

Positioning Accuracy: ±0.2 mm.

Cycle Time: ≤8 seconds per cell.

2.2 Cell-to-Busbar Laser Welding Station

Function: Performs high-precision laser welding to connect blade cell terminals to the busbar.

Specifications:

Welding Power: 600–1,500 W (fiber laser).

Welding Accuracy: ±0.05 mm.

Cycle Time: ≤5 seconds per weld.

Real-Time Monitoring: Inline monitoring system for weld quality with defect detection.

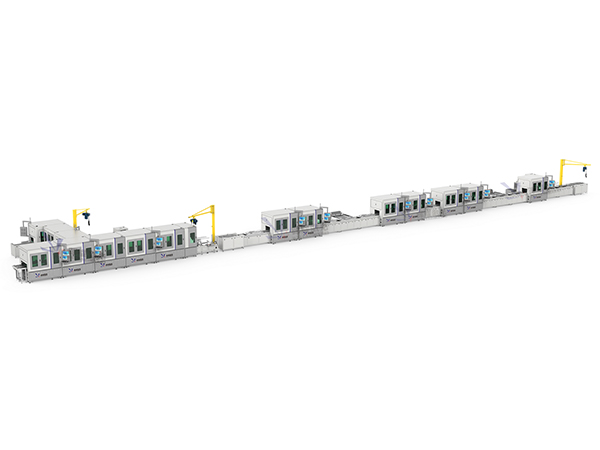

2.3 Thermal Management System Installation Station

Function: Installs cooling plates and applies thermal interface materials (TIM) to ensure efficient heat dissipation.

Specifications:

TIM Application Accuracy: ±0.1 mm.

Cooling Plate Compatibility: Liquid or air-cooling systems.

Cycle Time: ≤20 seconds per assembly.

2.4 Structural Bonding and Frame Assembly Station

Function: Bonds and assembles the structural frame around the blade cells for mechanical stability.

Specifications:

Adhesive Type: Epoxy or UV-curable adhesive.

Bonding Accuracy: ±0.2 mm.

Frame Material: Aluminum or composite material.

2.5 High-Voltage Busbar and Connector Welding Station

Function: Welds high-voltage connectors and busbars to create electrical paths between cells and the pack.

Specifications:

Welding Type: Laser or ultrasonic.

Welding Accuracy: ±0.05 mm.

Voltage Handling Capacity: Up to 1,000V DC.

Cycle Time: ≤10 seconds per connection

2.6 PACK Assembly and Sealing Station

Function: Assembles multiple blade modules into the pack housing and seals it to protect against environmental factors.

Specifications:

Sealant Material: Silicone or polymer gaskets.

Assembly Accuracy: ±0.3 mm.

Cycle Time: ≤3 minutes per PACK.

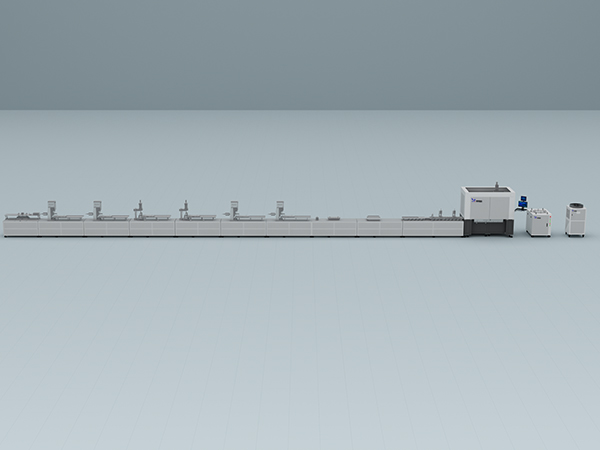

2.7 Electrical and Safety Testing Station

Function: Conducts comprehensive testing for electrical performance, insulation, and leakage.

Specifications:

Test Parameters: Voltage, resistance, insulation, short circuit, and leakage current.

Helium Leak Detection: Sensitivity ≤1x10⁻⁶ Pa·m³/s.

Testing Speed: ≤2 minutes per PACK.

2.8 Final Visual Inspection and Quality Assurance Station

Function: Automated inspection of weld quality, assembly alignment, and surface defects.

Specifications:

Vision System Resolution: 8 MP industrial cameras.

Inspection Speed: ≤1 minute per PACK.

AI Algorithm Accuracy: ±0.05 mm for defect detection.

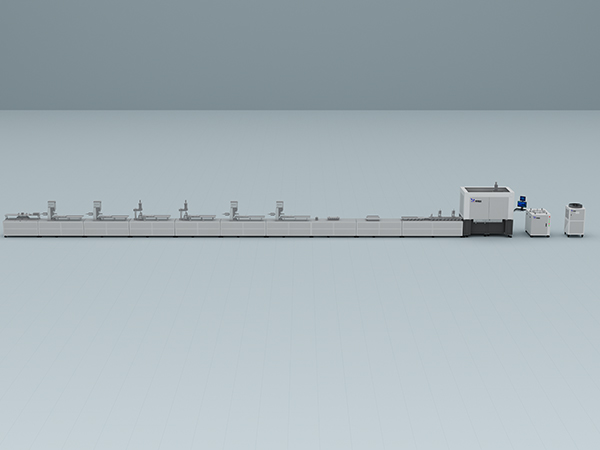

Overall Dimensions:

Length: 85,000 mm.

Width: 12,000 mm.

Height: 4,000 mm.

Weight: Approximately 55,000 kg.

Production Capacity: 12–15 PACKs/hour.

Automation Level: Fully automated with robotic handling and AI-powered monitoring.

Defect Detection: AI-driven system for weld and assembly defect detection.

Data Logging: Centralized database for traceability and production analytics.

Inspection Accuracy: ±0.05 mm for weld and surface defects.

Control System: Distributed PLC and HMI for centralized operation.

HMI Features:

17-inch touchscreen with multilingual support.

Real-time monitoring and diagnostics.

IoT Integration: Remote access for predictive maintenance and data analysis.

Enclosure Design: Fully enclosed with interlocks for safety.

Emergency Stops: Strategically placed along the line.

Laser Safety: Class 1 certified enclosures with auto shutdown on fault detection.

Electrical Protection: Surge and overcurrent protection systems.

Power Supply: AC 380V ±10%, 50/60 Hz, 3-phase.

Maximum Power Consumption: 320 kW.

Control Voltage: 24V DC for auxiliary systems.

Type: Centralized water cooling for welding and power systems.

Cooling Capacity: 150 kW.

Flow Rate: 40–60 L/min.

Operating Conditions:

Temperature: 15–30°C.

Humidity: ≤60% RH (non-condensing).

Noise Level: ≤75 dB during operation.

Installation Space: Minimum clearance of 2,000 mm around the line.

Maintenance Schedule:

Weekly: Check alignment, weld quality, and cooling systems.

Monthly: Calibrate vision and inspection tools.

Quarterly: Comprehensive diagnostics and software updates.

Warranty Period:

Standard: 12 months.

Extended: Available upon request.

EV Prismatic Battery Module PACK Assembly Line

EV Cylindrical Battery Module PACK Assembly Line

EV Pouch Battery Module PACK Line

EV Blade Battery Module PACK Line

EV Prismatic Battery CTP Automatic Welding Line

ESS Prismatic Battery Module PACK Assembly Line

EV Cylindrical Battery Module PACK Assembly Lines

Prismatic Battery Cap Manufacture Line

Email: sales@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.