Turnkey Solution for New Energy Intelligent Equipment

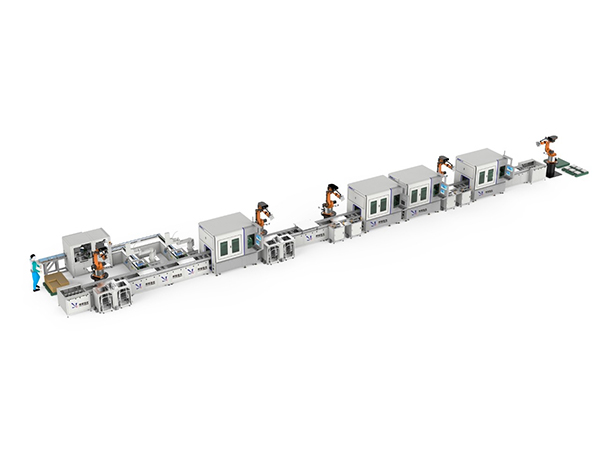

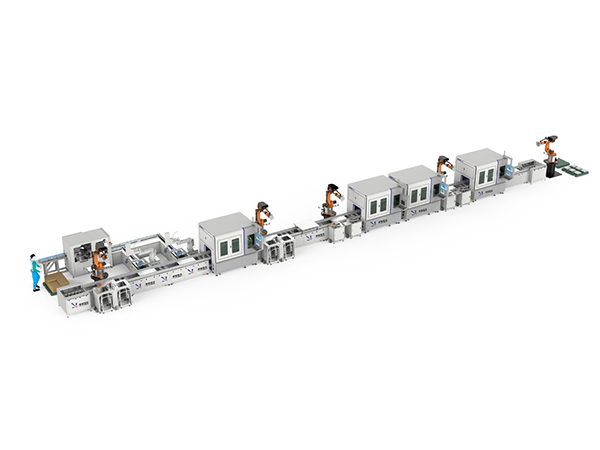

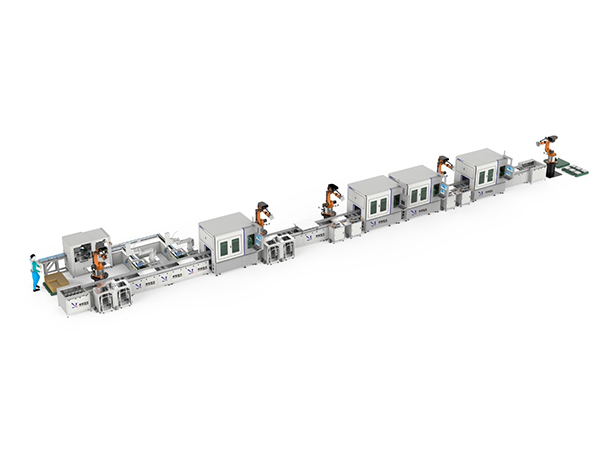

The EV Pouch Battery Module PACK Assembly Line is a fully automated production system designed for assembling pouch cells into battery modules and complete PACKs. It integrates processes such as cell sorting, stacking, welding, cooling system integration, and final testing. The line ensures high precision, consistency, and scalability for electric vehicle battery manufacturing.

Categories: Lithium Battery PACK Assembly REQUEST FOR QUOTE > TURN BACKThe EV Pouch Battery Module PACK Assembly Line is a fully automated production system designed for assembling pouch cells into battery modules and complete PACKs. It integrates processes such as cell sorting, stacking, welding, cooling system integration, and final testing. The line ensures high precision, consistency, and scalability for electric vehicle battery manufacturing.

2.1 Battery Cell Sorting and Grouping Station

Function: Automatically sorts and groups pouch cells based on electrical parameters such as voltage, capacity, and internal resistance.

Specifications:

Sorting Accuracy: ±1 mV (voltage), ±0.1 mΩ (resistance).

Sorting Capacity: 150 cells/hour.

2.2 Automatic Cell Stacking Station

Function: Aligns and stacks pouch cells into precise module configurations.

Specifications:

Stacking Method: Robotic alignment and vacuum handling.

Alignment Accuracy: ±0.1 mm.

Stacking Speed: ≤10 seconds per cell.

2.3 Busbar and Tab Welding Station

Function: Welds tabs and busbars for electrical interconnection.

Specifications:

Welding Type: Fiber laser or ultrasonic welding.

Welding Accuracy: ±0.05 mm.

Welding Speed: ≤5 seconds per weld.

Weld Quality Monitoring: Integrated real-time quality inspection.

2.4 Module Frame Assembly Station

Function: Assembles pouch cells into a structural frame for mechanical stability.

Specifications:

Frame Material: Aluminum or polymer composites.

Assembly Accuracy: ±0.2 mm.

Cycle Time: ≤15 seconds per module.

2.5 Thermal Management Integration Station

Function: Installs cooling plates or liquid cooling systems and applies thermal interface materials (TIM).

Specifications:

TIM Application Accuracy: ±0.1 mm.

Cooling Plate Compatibility: Customizable for liquid or air cooling systems.

Integration Speed: ≤30 seconds per module

2.6 Module and PACK Assembly Station

Function: Assembles multiple modules into a battery PACK, including high-voltage connectors and structural enclosures.

Specifications:

PACK Size Range:

Length: 600–1200 mm.

Width: 400–800 mm.

Height: 150–500 mm.

Assembly Accuracy: ±0.3 mm.

Cycle Time: ≤120 seconds per PACK.

2.7 Electrical and Functional Testing Station

Function: Performs comprehensive electrical, functional, and safety tests on modules and PACKs.

Specifications:

Testing Parameters: Voltage, current, internal resistance, insulation resistance, and short-circuit testing.

Testing Speed: ≤2 minutes per module/PACK.

Data Logging: Automated data storage for traceability.

2.8 Final PACK Inspection and Quality Control Station

Function: Conducts visual inspection and quality assurance tests, including helium leak detection and insulation integrity.

Specifications:

Leak Detection Sensitivity: ≤1x10⁻⁶ Pa·m³/s.

Inspection Speed: ≤2 minutes per PACK.

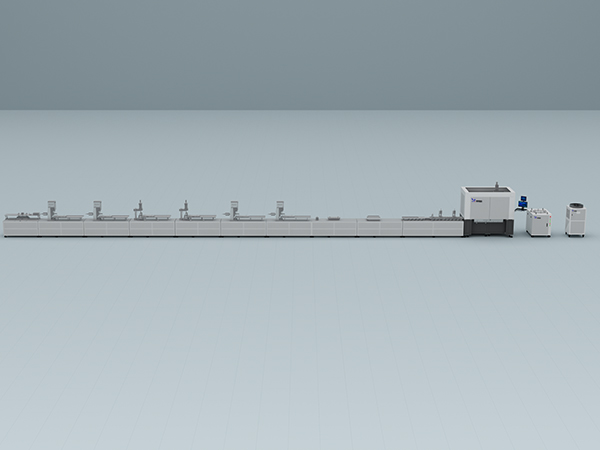

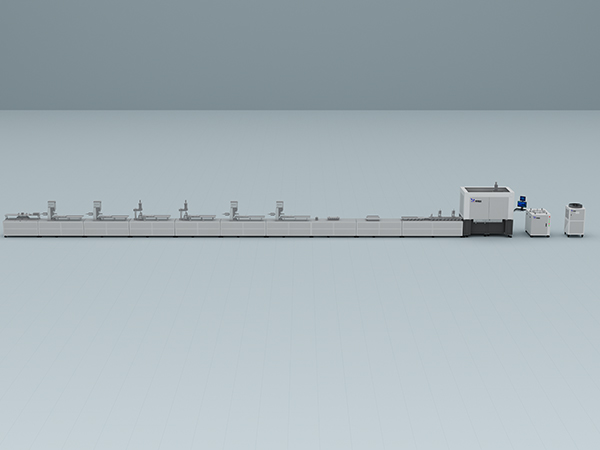

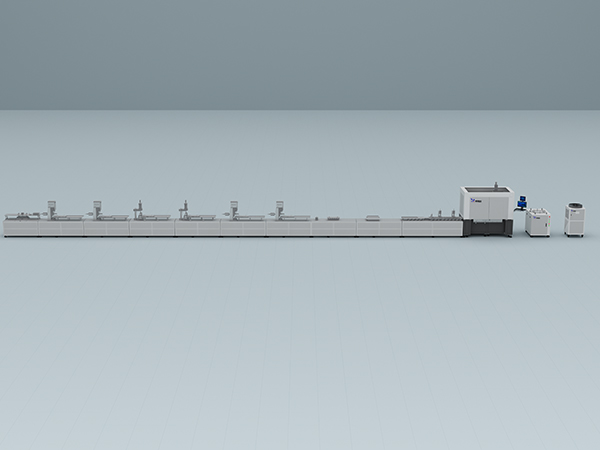

Overall Dimensions:

Length: 65,000 mm.

Width: 10,000 mm.

Height: 3,500 mm.

Weight: Approximately 35,000 kg.

Production Capacity: Up to 20 PACKs/hour.

Automation Level: Fully automated with advanced robotics and vision systems.

Alignment Cameras:

Resolution: 5 MP high-speed cameras.

Alignment Accuracy: ±0.02 mm.

Defect Detection: AI-powered algorithms for tab misalignment, welding defects, and frame assembly errors.

Data Management: Inspection results stored in a centralized database for analysis and traceability

Control System: Advanced PLC with distributed control for modular flexibility.

Human-Machine Interface (HMI):

15-inch touchscreen with multi-language options.

Real-time monitoring and diagnostics.

IoT and Cloud Integration:

Remote monitoring, predictive maintenance, and production analytics.

Enclosure Design: Fully enclosed with safety interlocks and emergency stop buttons.

Laser Safety: Class 1 laser enclosures with certified safety glass.

Electrical Safety: Overcurrent and short-circuit protection.

Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

Maximum Power Consumption: 200 kW.

Control Voltage: 24V DC for auxiliary systems.

Type: Centralized water cooling for welding and power systems.

Cooling Capacity: 80 kW.

Flow Rate: 30–50 L/min.

Operating Environment:

Temperature: 15–30°C.

Humidity: ≤60% RH (non-condensing).

Noise Level: ≤75 dB during operation.

Installation Space: Minimum clearance of 2,000 mm around the line.

Maintenance Schedule:

Weekly: Inspect alignment, welding, and cooling systems.

Monthly: Calibrate vision systems and test stations.

Quarterly: Comprehensive diagnostics and software updates.

Warranty Period:

Standard: 12 months.

Extended: Available upon request.

EV Prismatic Battery Module PACK Assembly Line

EV Cylindrical Battery Module PACK Assembly Line

EV Blade Battery Module PACK Line

EV Prismatic Battery CTP Automatic Welding Line

EV Blade Battery CTP Automatic Welding Line

ESS Prismatic Battery Module PACK Assembly Line

EV Cylindrical Battery Module PACK Assembly Lines

Prismatic Battery Cap Manufacture Line

Email: sales@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.