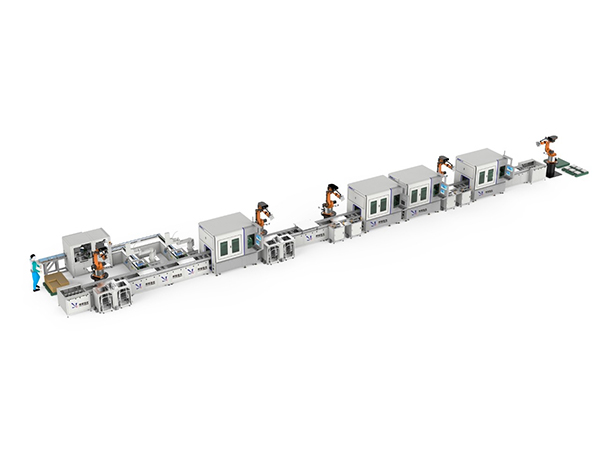

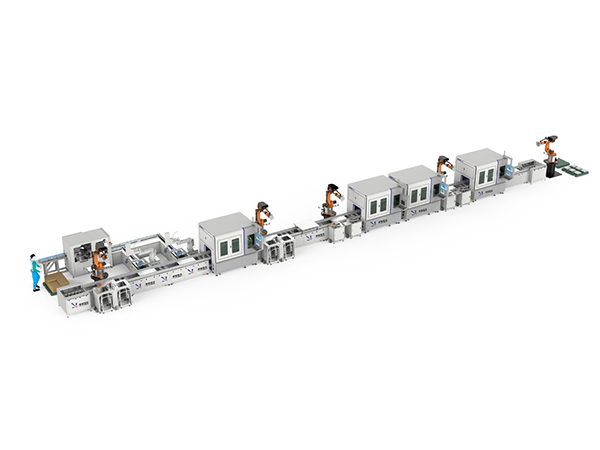

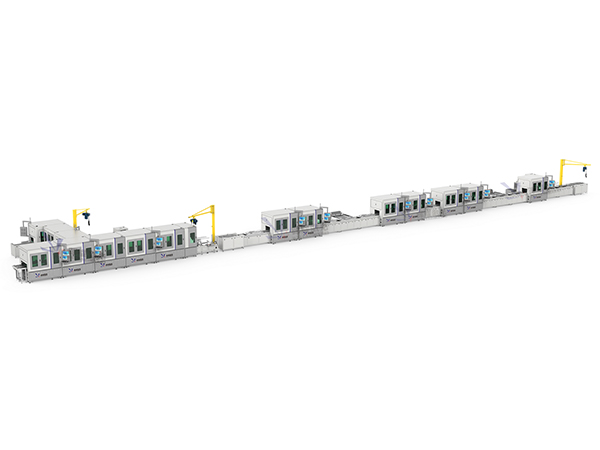

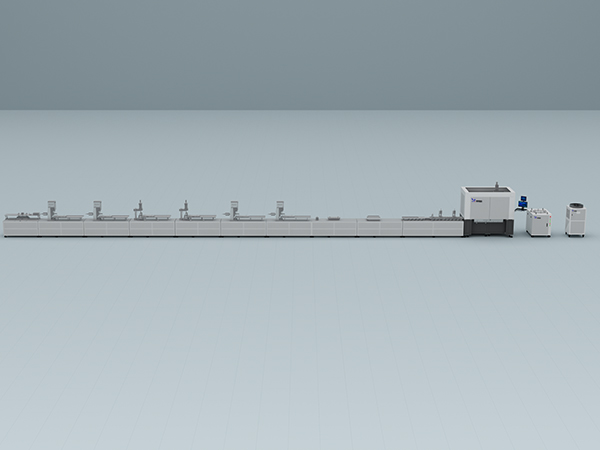

Turnkey Solution for New Energy Intelligent Equipment

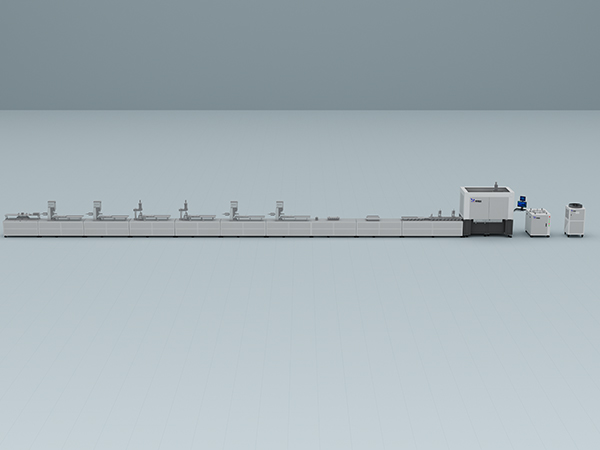

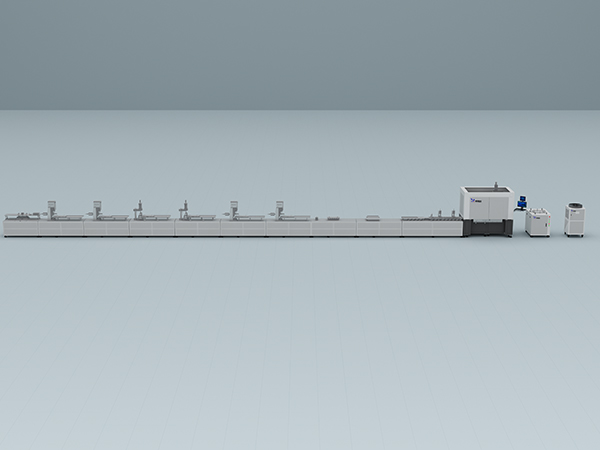

Equipment Name: Prismatic Battery Manufacturing Line Model: HY-PBML5000 Application: Fully automated production line for prismatic battery cells, integrating critical processes such as explosion-proof valve welding, cover plate assembly welding, air-tightness testing, and impedance/performance testing. Production Capacity: 20–30 cells per minute (process-dependent).

Categories: Lithium Battery PACK Assembly REQUEST FOR QUOTE > TURN BACKEquipment Name: Prismatic Battery Manufacturing Line

Model: HY-PBML5000

Application: Fully automated production line for prismatic battery cells, integrating critical processes such as explosion-proof valve welding, cover plate assembly welding, air-tightness testing, and impedance/performance testing.

Production Capacity: 20–30 cells per minute (process-dependent).

Equipment Dimensions:

Length: 15,000 mm

Width: 3,000 mm

Height: 2,200 mm

Weight: 8,500 kg ± 5%

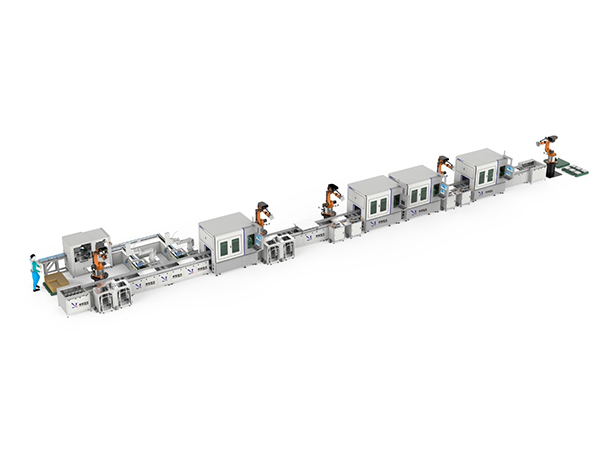

Modular Structure: Individual stations interconnected with a conveyor system.

Frame Material: High-strength steel with powder-coated surface for corrosion resistance.

Worktable Material: Stainless steel with anti-static properties.

3.1 Explosion-Proof Valve Welding Station

Welding Method: Precision laser welding.

Laser Specifications:

Wavelength: 1064 nm.

Power: 200 W (adjustable).

Welding Speed: 1–3 seconds per valve.

Welding Accuracy: ±0.02 mm.

Material Compatibility: Aluminum, stainless steel.

Vision System:

High-resolution CCD camera for precise valve alignment.

Real-time monitoring of weld quality.

3.2 Cover Plate Assembly Welding Station

Welding Method: Resistance or ultrasonic welding.

Welding Current: 50–500 A (programmable).

Welding Speed: 8–12 welds per minute.

Alignment Accuracy: ±0.03 mm.

Cover Plate Size Compatibility:

Length: 50–200 mm

Width: 30–100 mm

Material Compatibility: Aluminum, nickel-coated steel.

Pre-Welding Verification: Sensor-based detection of proper plate placement.

3.3 Air Tightness Testing Station

Testing Method: Helium leak detection.

Detection Range:

Minimum Leak Rate: 1 × 10⁻⁶ mbar·L/s.

Maximum Leak Rate: 1 × 10⁻² mbar·L/s.

Cycle Time: ≤20 seconds per cell.

Vacuum Chamber Dimensions:

Length: 50–300 mm

Width: 50–200 mm

Height: 5–100 mm

Helium Recovery Efficiency: ≥98%.

Pass/Fail Criteria: Configurable based on customer specifications.

3.4 Impedance and Performance Testing Station

Testing Parameters:

Internal Resistance (Impedance): 0.01–100 mΩ (accuracy: ±0.001 mΩ).

Voltage Range: 0–100 V (accuracy: ±0.01 V).

Current Range: 0–200 A (accuracy: ±0.1 A).

Testing Speed: Up to 30 cells per minute.

Performance Metrics: Conducts charge/discharge cycle simulation and resistance measurements.

Data Storage:

Internal Storage: 2 TB SSD for test results.

Export Formats: CSV, PDF via USB, Ethernet, or cloud.

4. Conveyor System Specifications

Transport Speed: Adjustable, up to 12 m/min.

Conveyor Material: ESD-safe belt with wear-resistant coating.

Load Capacity: 10–15 kg per cell.

Positioning Accuracy: ±0.05 mm with servo-driven indexing.

5. Control and Interface

Control System: PLC-based centralized system with integrated monitoring.

HMI:

15-inch capacitive touchscreen with multi-language support.

Intuitive GUI for station control and monitoring.

Data Management:

Recipe storage for different battery models.

Real-time analytics for production and quality metrics.

Communication Protocols: Modbus, Ethernet/IP, and OPC UA for factory integration.

6. Electrical Specifications

Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

Maximum Power Consumption: 20 kW (entire line).

Control Voltage: 24V DC for auxiliary systems.

7. Safety Features

Emergency Stop: Multiple emergency stop buttons at each station.

Overload Protection: Integrated sensors for load monitoring in conveyors and welding stations.

Laser Safety: Class 1 laser enclosures with interlocks and safety curtains.

Helium Leak Detection Alarms: Audible and visual alerts for excessive leak rates.

Protective Barriers: Transparent enclosures with interlocks for operator safety.

8. Environmental and Installation Requirements

Operating Environment:

Temperature: 15–30°C

Humidity: ≤60% RH (non-condensing).

Noise Level: ≤75 dB during operation.

Installation Requirements:

Flat, vibration-free surface.

Minimum clearance: 1,000 mm around the equipment.

9. Optional Configurations

Dual Welding Heads: For higher throughput at welding stations.

Advanced Vision System: AI-based defect detection for welding and assembly processes.

Automated Loading/Unloading: Robotic integration for material handling.

IoT Connectivity: Cloud-based monitoring and remote diagnostics.

Maintenance Schedule:

Weekly: Inspect welding heads, check conveyor alignment, and clean vacuum chambers.

Monthly: Calibrate test stations and verify alignment systems.

Quarterly: Comprehensive diagnostics of electrical and mechanical systems.

Warranty Period:

Standard: 12 months.

Extended: Up to 36 months available upon request.

EV Prismatic Battery Module PACK Assembly Line

EV Cylindrical Battery Module PACK Assembly Line

EV Pouch Battery Module PACK Line

EV Blade Battery Module PACK Line

EV Prismatic Battery CTP Automatic Welding Line

EV Blade Battery CTP Automatic Welding Line

ESS Prismatic Battery Module PACK Assembly Line

EV Cylindrical Battery Module PACK Assembly Lines

Email: sales@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.