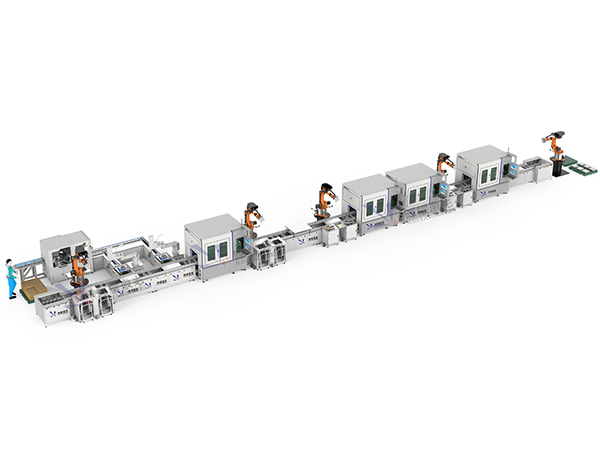

Turnkey Solution for New Energy Intelligent Equipment

Equipment Dimensions: Length: 2000 mm Width: 1500 mm Height: 1800 mm Weight: 1200 kg ± 5% Frame Material: High-strength steel with anti-corrosion coating. Worktable Material: Stainless steel with anti-static properties. Test Chamber Size: Length: 50–300 mm Width: 50–200 mm Height: 5–100 mm (adjustable).

Categories: Lithium Battery Testing Equipment REQUEST FOR QUOTE > TURN BACKEquipment Name: Battery Helium Leak Detection Equipment

Model: HY-HLD1010

Application: Precision helium leak detection for prismatic, cylindrical, and pouch battery cells to ensure airtight sealing and safety compliance in battery manufacturing processes.

Equipment Dimensions:

Length: 2000 mm

Width: 1500 mm

Height: 1800 mm

Weight: 1200 kg ± 5%

Frame Material: High-strength steel with anti-corrosion coating.

Worktable Material: Stainless steel with anti-static properties.

Test Chamber Size:

Length: 50–300 mm

Width: 50–200 mm

Height: 5–100 mm (adjustable).

Detection Method: Helium mass spectrometry.

Leak Rate Sensitivity:

Minimum Detectable Rate: 1 × 10⁻⁶ mbar·L/s.

Maximum Detectable Rate: 1 × 10⁻² mbar·L/s.

Testing Accuracy: ±0.05 mbar·L/s.

Helium Injection Pressure: 0.1–0.5 MPa (adjustable).

Cycle Time:

Single Cell Test: ≤30 seconds (including evacuation and measurement).

Batch Test: Configurable based on chamber size.

Helium Recovery Rate: ≥98%.

Control System: PLC-based system with integrated HMI for test parameter configuration.

Interface:

12-inch capacitive touchscreen with multi-language support.

Intuitive graphical user interface (GUI) for real-time monitoring and diagnostics.

Programmable Parameters:

Helium injection pressure.

Leak detection threshold.

Test cycle time.

Recipe storage for various battery types and sizes.

Data Logging:

Internal Storage: 1 TB SSD for historical test data.

Export Formats: CSV, PDF via USB, Ethernet, or Wi-Fi.

Vacuum Pump Type: Dual-stage rotary vane pump with oil mist eliminator.

Ultimate Vacuum Level: ≤1 × 10⁻³ mbar.

Pumping Speed: 50–200 L/min (process-dependent).

Vacuum Chamber Seal: High-strength silicone gasket with excellent durability.

Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

Maximum Power Consumption: 6 kW.

Control Voltage: 24V DC for auxiliary systems.

Emergency Stop: Dual emergency stop buttons on front and rear panels.

Pressure Monitoring: Real-time helium injection and evacuation pressure sensors with alarms for anomalies.

Vacuum Chamber Safety:

Overpressure relief valves.

Automatic chamber lock during operation.

Leak Detection Failure Alert: Audible and visual alarm for leaks exceeding preset thresholds

Helium Recovery Safety: Continuous monitoring of recovery system to prevent helium loss or contamination.

Operating Environment:

Temperature: 15–30°C

Humidity: ≤60% RH (non-condensing).

Noise Level: ≤75 dB during operation.

Installation Requirements:

Flat, vibration-free surface.

Clearance: Minimum 800 mm on all sides.

Maintenance Schedule:

Weekly: Inspect vacuum seals, clean filters, and check helium recovery system.

Monthly: Calibrate helium sensors and inspect vacuum pump oil levels.

Quarterly: Comprehensive system calibration and vacuum chamber inspection.

Warranty Period:

Standard: 12 months.

Extended: Up to 36 months available upon request.

EV Battery Cell Capacity Grading Cabinet

EV Battery Cell Performance Testing Cabinet

EV Battery Module PACK Aging Cabinet

EV Battery Module PACK Performance Testing Cabinet

EV Battery Module PACK BMS Testing System

EV Battery Module PACK End-of-Line (EOL) Testing System

ESS Battery Cell Capacity Grading Cabinet

ESS Battery Cell Performance Testing Cabinet

Email: sales@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.