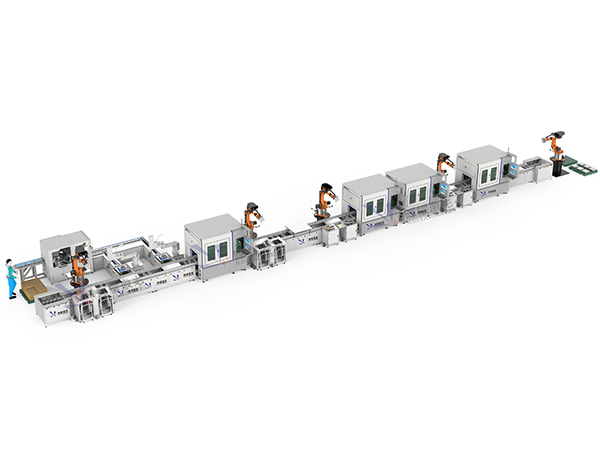

Turnkey Solution for New Energy Intelligent Equipment

The ESS Battery Module PACK End-of-Line (EOL) Testing System is a comprehensive solution for validating the final quality and performance of energy storage system (ESS) battery modules and PACKs. Designed to simulate real-world operational scenarios, this system ensures each module or PACK meets stringent industry standards before deployment. The system supports high-accuracy testing, data analysis, and efficient testing workflows for large-scale production environments.

Categories: Lithium Battery Testing Equipment REQUEST FOR QUOTE > TURN BACKThe ESS Battery Module PACK End-of-Line (EOL) Testing System is a comprehensive solution for validating the final quality and performance of energy storage system (ESS) battery modules and PACKs. Designed to simulate real-world operational scenarios, this system ensures each module or PACK meets stringent industry standards before deployment. The system supports high-accuracy testing, data analysis, and efficient testing workflows for large-scale production environments.

Supported Formats: Prismatic, pouch, and cylindrical module/PACK configurations.

Size Range:

Minimum: 300 × 200 × 50 mm.

Maximum: 1,500 × 1,000 × 300 mm.

Weight Capacity: Up to 200 kg per module/PACK.

Voltage Testing:

Range: 0–1,000 V.

Accuracy: ±0.05%.

Current Testing:

Range: 0–500 A.

Accuracy: ±0.1%.

Capacity Testing:

Range: 0–1,000 Ah.

Accuracy: ±0.1%.

Internal Resistance Testing:

Range: 0.01–50 mΩ.

Accuracy: ±0.05 mΩ.

Key Parameters Evaluated:

Overvoltage/undervoltage protection.

Overcurrent/short-circuit protection.

Temperature monitoring performance.

SOC (State of Charge) and SOH (State of Health) accuracy.

Insulation resistance and dielectric strength.

Cycle Testing: Supports multiple charge/discharge cycles to simulate long-term operation.

Parallel Channels: 8–32 channels (configurable).

Testing Throughput: Up to 20 modules or PACKs per batch (depending on size and configuration).

Real-Time Monitoring: Tracks voltage, current, resistance, and thermal behavior during tests.

Traceability: Unique ID tracking for each module/PACK.

Data Logging: High-resolution data storage for performance analysis and fault diagnosis.

Reporting: Automated generation of customizable test reports.

Integration: Compatible with MES/ERP systems for centralized monitoring and analysis

HMI: 12-inch touchscreen for user-friendly operation.

Software: Advanced testing software with customizable profiles and real-time monitoring.

Communication Protocols: CAN, RS485, RS232, and Ethernet for interfacing with BMS.

Electrical Protection: Overcurrent, overvoltage, and short-circuit protections.

Thermal Monitoring: Alerts for overheating or thermal deviations.

Emergency Shutdown: Physical and software-activated emergency stop functions.

Fire Suppression: Optional fire suppression system for high-capacity modules/PACKs.

Dimensions: 2,500 × 1,500 × 2,200 mm (customizable).

Weight: Approximately 3,000 kg.

Cabinet Structure: Modular design for efficient testing and maintenance.

Cooling System: Integrated forced-air cooling or optional liquid cooling for high-capacity tests.

Input Voltage: AC 380V ±10%, 50/60 Hz, 3-phase.

Power Consumption: ≤120 kW.

Operating Temperature: 15–35°C.

Humidity: ≤70% RH (non-condensing).

Environment: Clean and dust-free area recommended for optimal operation.

Energy Storage Systems (ESS): Final validation for battery modules and PACKs used in grid stabilization and renewable energy storage.

Commercial and Industrial ESS: Ensures compliance with quality standards for large-scale deployments.

Renewable Energy Integration: Tests modules and PACKs designed for solar and wind energy storage systems.

Maintenance Schedule:

Weekly: Inspect connectors and test interfaces.

Monthly: Verify calibration of testing instruments.

Annually: Comprehensive diagnostics and system updates.

Warranty:

Standard: 1 year.

Extended: Optional packages available.

EPrismatic Battery Helium Leak Detection Equipment

EV Battery Cell Capacity Grading Cabinet

EV Battery Cell Performance Testing Cabinet

EV Battery Module PACK Aging Cabinet

EV Battery Module PACK Performance Testing Cabinet

EV Battery Module PACK BMS Testing System

EV Battery Module PACK End-of-Line (EOL) Testing System

ESS Battery Cell Capacity Grading Cabinet

Email: sales@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.