Turnkey Solution for New Energy Intelligent Equipment

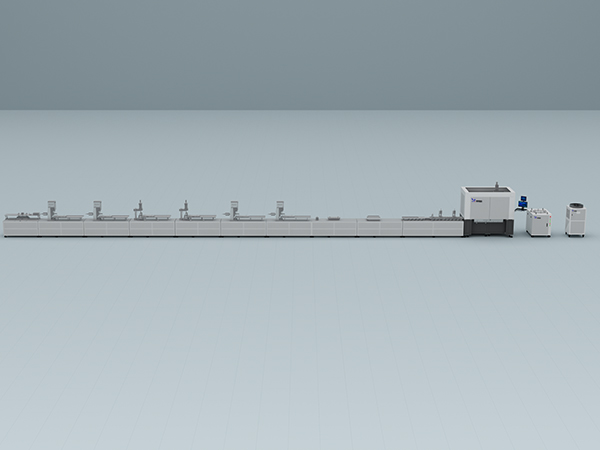

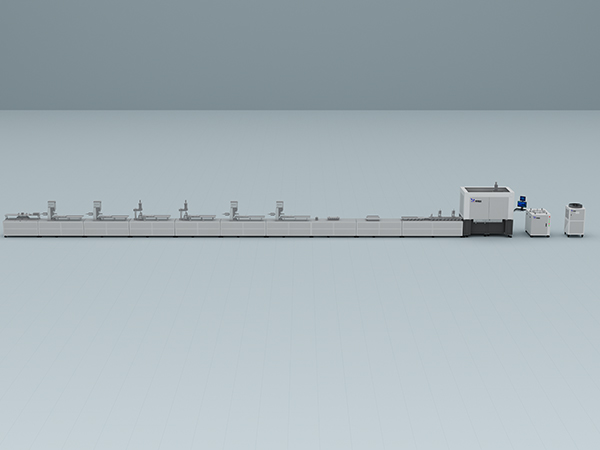

The EV Blade Battery Module PACK Assembly Line is an advanced, automated production system specifically designed for the assembly of blade-type battery cells into modules and PACKs. This line ensures high efficiency, precision, and safety by integrating cell sorting, module assembly, welding, thermal management system installation, and comprehensive testing. It is tailored for large-scale electric vehicle (EV) battery manufacturing.

Inquire Now

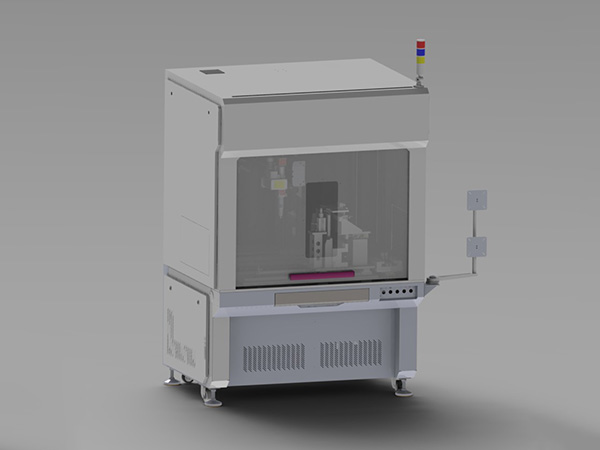

The ESS Battery Cell Capacity Grading Cabinet is a high-precision system designed for grading energy storage battery cells based on their capacity, voltage, and internal resistance. This equipment is optimized for ESS applications and ensures consistent quality and performance by identifying cells with similar characteristics for balanced module and pack assembly.

Inquire Now

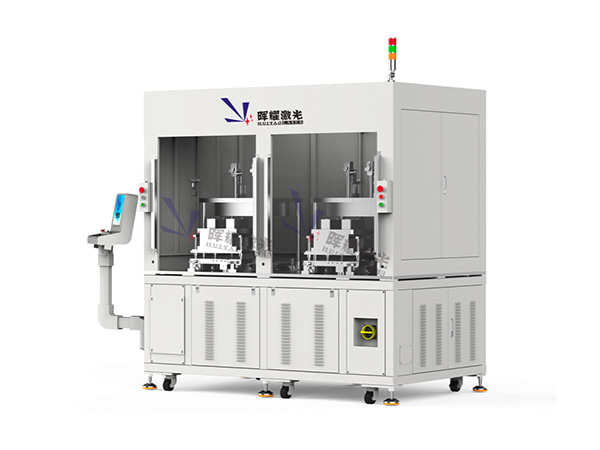

Battery Top Cap Welding Equipment Equipment Dimensions: Length: 1800 mm Width: 1400 mm Height: 1900 mm Weight: 1300 kg ± 5% Frame Material: High-strength steel frame with powder coating for durability. Worktable Material: Anodized aluminum with anti-static and wear-resistant surface. Motion System: Precision servo-driven X-Y-Z axes with linear guide rails.

Inquire Now

The EV Prismatic Battery CTP (Cell-to-Pack) Automatic Welding Line is a high-performance, fully automated production line for assembling prismatic cells directly into battery packs without using traditional modules. The system integrates advanced welding technologies, precision handling, and quality inspection processes to ensure structural integrity and electrical performance. Designed for large-scale EV battery manufacturing, it enables efficient, scalable, and cost-effective production.

Inquire Now

The ESS Battery Cell Performance Testing Cabinet is a high-precision system designed to evaluate the electrical and thermal performance of energy storage system (ESS) battery cells. It conducts a comprehensive analysis of capacity, efficiency, thermal behavior, and durability under varied operational conditions. The cabinet is engineered to ensure reliability and consistency for cells used in ESS applications.

Inquire Now

Equipment Dimensions: Length: 1800 mm Width: 1500 mm Height: 1900 mm Weight: 1200 kg ± 5% Frame Material: High-strength steel frame with anti-corrosion coating. Worktable Material: Anodized aluminum alloy with wear-resistant and anti-static surface. Motion System: Servo-controlled X-Y-Z axes with high-precision linear guide rails.

Inquire Now

Email: sales@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.