Turnkey Solution for New Energy Intelligent Equipment

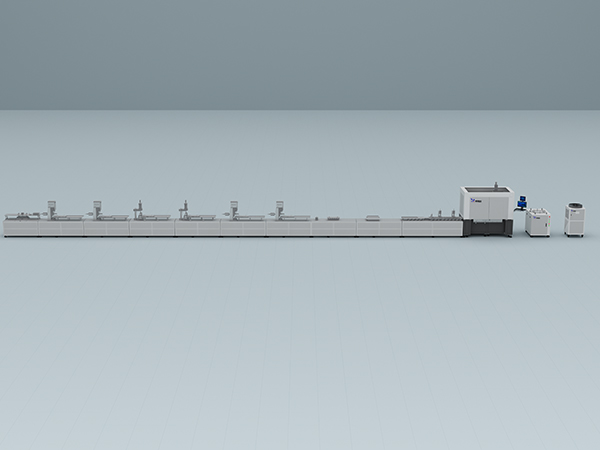

The EV Blade Battery CTP (Cell-to-Pack) Automatic Welding Line is a cutting-edge automated solution tailored for the direct assembly of blade battery cells into robust packs without intermediate modules. This line combines high-precision handling, advanced laser welding, and quality inspection systems to ensure efficient, high-throughput production while meeting the demanding safety and performance requirements of EV batteries.

Inquire Now

The ESS Battery Module PACK Aging Cabinet is specifically designed to evaluate the aging characteristics of energy storage battery modules and packs. This cabinet simulates long-term use conditions by performing charge and discharge cycles to assess capacity fade, efficiency degradation, and thermal stability over time. The system is engineered for ESS applications, ensuring quality and reliability for modules and packs.

Inquire Now

Equipment Dimensions: Length: 1200 mm Width: 800 mm Height: 1800 mm Weight: 950 kg ± 5% Frame Material: High-strength carbon steel with powder-coated finish. Actuation System: Precision servo motor with ball screw-driven pressing mechanism.

Inquire Now

The Manufacturing Execution System (MES) for EV Smart Factory Solutions is a fully integrated software platform designed to manage, monitor, and optimize production processes in real-time. It facilitates seamless communication across production, logistics, quality control, and data analysis, ensuring operational efficiency, traceability, and compliance with industry standards.

Inquire Now

The ESS Battery Module PACK Performance Testing Cabinet is designed for high-precision electrical and thermal performance testing of energy storage system (ESS) battery modules and packs. It ensures comprehensive evaluation of voltage, current, capacity, and resistance, verifying compliance with stringent quality standards for ESS applications. This system is ideal for module/PACK manufacturers and operators to validate performance under real-world operating conditions.

Inquire Now

Equipment Dimensions: Length: 1500 mm Width: 1000 mm Height: 1800 mm Weight: 1200 kg ± 5% Frame Material: Reinforced steel frame with anti-corrosion coating. Worktable Material: Hardened stainless steel with fine polishing for low friction. Motion System: Linear motor-driven X-Y-Z axes with high repeatability.

Inquire Now

Email: sales@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.